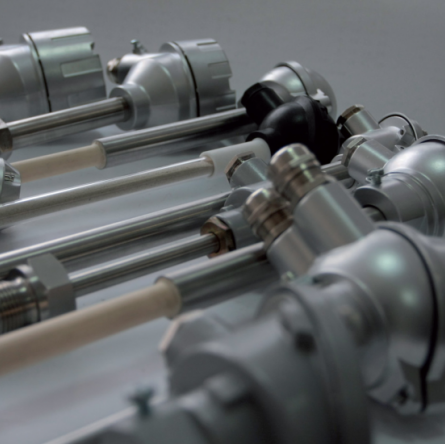

Nonstandard measuring constructions

of industrial temperature sensors.

Reprint from PAR magazine 5/2012

The contemporary automation market sets high technical requirements for measuring applications. Limatherm Sensor is the leading producer of equipment for temperature measurements. Experience gathered through years allows us to control and modernize the production processes in compliance with the increasing technical-constructional requirements of this market.

Temperature sensor has always been associated with the simple sensing element included in the measuring system. Nowadays, each type of such system requires the use of individual construction created only for the dedicated application.

Temperature sensor has always been associated with the simple sensing element included in the measuring system. Nowadays, each type of such system requires the use of individual construction created only for the dedicated application.

The diversity of constructional requirements obligates us to designing, testing and sensor production with care of the highest quality and reliability of operating in the most difficult environments.

To prepare such an individual solution a close cooperation between the end user, sales representative and designer is required. The designer creates the special documentation, on the basis of customer specifications, that is called Karta uzgodnień (Card of arrangements) with unique number included in the symbol of the manufactured element.

For example, sensor code TOPGN-11-KU528/2012 contains information that this construction is based on the construction of the temperature sensor with replaceable measuring insert TOPGN-11, but its specific properties are described in Limatherm Sensor internal documentation numbered 528/2012.

It usually takes a few days to prepare an unusual construction and documentation (according to the specific measuring solutions). It takes few or several dozen days to produce a sensor on the basis of such documentation.

Specific requirements of medium and surrounding frequently determine the necessity to use components resistant to these conditions, which availability on the market is, unfortunately, highly restricted. Very often the construction is modified to meet the increased requirements of application as well as improve and modernize, at the same time, measuring process.

Limatherm Sensor creates about 300-400 documents of this type per year, and produces from 1 to 200 pieces of measuring elements of each type (acc. to statistics from the last 3 years).

Our major successful projects are, e.g.:

- Temperature measurement during the process of catalytic decomposition of ammonia

- Temperature measurement with the aid of elements dedicated for axle box in railway industry

- Temperature measurement during the process of caprolactam extraction

We would like to encourage everyone who is interested to cooperate with Limatherm Sensor in case of nonstandard applications with high requirements. Each measurement is a challenge for us, and a chance to gain new experience and keep the leading position in production of industrial temperature sensors and measuring equipment.

Jarosław Włodarczyk

mgr inż. Andrzej Kazana mgr inż. Andrzej KazanaLimatherm Sensor Chief Designer Preparation of documentation (Karta Uzgodnień) is the most time-consuming and complicated stage that influences strongly the final product. All shortcomings shall be eliminated at this stage in order to avoid later costs of mechanic modernization of project. The main aim of Limatherm Sensor Design Department is to adjust completely our customer requirements to technical requirements of a measuring device realization. |